汙泥回流偏心螺杆泵,汙泥擠壓泵,汙泥進料螺杆泵選型參數

時間:2013/3/30 來源(yuán):浙(zhè)江香蕉视频网站江泵業有限公司

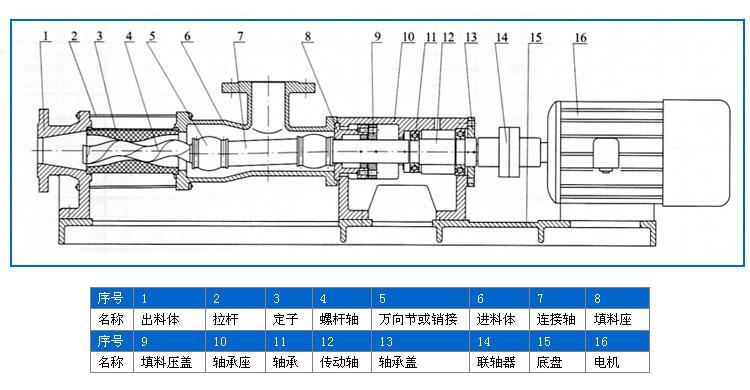

G型單螺杆泵因橡膠桶選(xuǎn)用多種彈性材料製成,所(suǒ)以這種(zhǒng)G型單螺杆泵可以輸送粘度達到80%流體的輸送和含有硬質懸(xuán)浮顆粒介質或含有纖維介質的輸送,有一般泵種所不能勝任的特性。其流量與(yǔ)轉速成正比,G型單螺杆泵(bèng)結構緊湊,體(tǐ)積小,維修簡(jiǎn)便。對(duì)介質的適應性(xìng)強,流量平穩,壓力脈動(dòng)小,自吸能力高。工作溫度可達120℃,如果需輸送120℃-350℃高溫介質,可定做。廣泛用於食品、冶金(jīn)、造紙、印染、化工(gōng)、化肥、製藥等工業部(bù)門。

一、汙泥回流偏心(xīn)螺杆泵,汙泥擠壓泵,汙泥進料螺杆泵性能參數(試驗介(jiè)質20℃清水)

|

標準 型號 Standard model |

每(měi)100轉理論(lùn)流量 Theoretical flow(L)/100 revolutions |

允許工作壓力(MPa) Allowable max particulate size (mm) |

允許大顆粒粒徑(mm) Allowable max particulate size(mm) |

轉速流量近(jìn)似成正比關係(xì) Rotation flow is approximate to proportion |

泵合(hé)理流量範圍(m3/h) Rational flow range of pump(m3/h) |

佳工作 轉速 Optimum working rotation velocity(r/min) |

配套電機 功率(KW) Power of the matching motor(kw) |

吸(xī)入法蘭

Pump-in flange |

排出法蘭 Pump-out flange |

配套代號 與方式 Matching code and mode | ||||

|

泵400r/min 時流量(M3/h) Flow(m3/h)when the pump is 400r/min |

孔徑 (mm) Orifice size (mm) |

通徑 (mm) Though oath (mm) |

孔徑 (mm) Orifice size (mm) |

通徑 (mm) through path (mm) |

可選方式(代號) Options(code) |

有以下多種配套方式 A suite of configuration available as shown as below | ||||||||

|

G15-1 |

1.63 |

0-0.6 |

3 |

0.3 |

0.3-0.8 |

400-1000 |

0.55-0.75 |

125 |

50 |

110 |

40 |

1.2.3.4.

5. |

| |

|

G15-2 |

1.63 |

0-12 |

3 |

0.3 |

0.3-0.8 |

400-1000 |

0.75-1.1 |

125 |

50 |

110 |

40 | |||

|

G15-3 |

1.63 |

0-18 |

3 |

0.3 |

0.3-0.8 |

400-1000 |

1.1-1.5 |

125 |

50 |

110 |

40 | |||

|

G15-4 |

1.63 |

0-2.4 |

3 |

0.3 |

0.3-0.8 |

400-1000 |

1.5-2.2 |

125 |

50 |

110 |

40 | |||

|

G25-1 |

6.27 |

0-0.6 |

5 |

1.2 |

1-3.4 |

400-900 |

1.1-1.5 |

125 |

50 |

110 |

40 | |||

|

G25-2 |

6.27 |

0-1.2 |

5 |

1.2 |

1-3.4 |

400-900 |

1.5-2.2 |

125 |

50 |

110 |

40 | |||

|

G25-1A |

12.65 |

0-0.6 |

5 |

2.4 |

2-5.5 |

400-900 |

1.5-2.2 |

125 |

50 |

110 |

40 | |||

|

G35-1 |

13.11 |

0-0.6 |

6 |

2.7 |

4-6 |

400-900 |

2.2-3 |

145 |

65 |

145 |

65 | |||

|

G35-2 |

13.11 |

0-1.2 |

6 |

2.7 |

4-6 |

400-900 |

3-4 |

145 |

65 |

145 |

65 | |||

|

G40-1 |

24.91 |

0-0.6 |

8 |

5.0 |

6-8 |

400-800 |

2.2-3 |

145 |

65 |

145 |

65 | |||

|

G40-2 |

24.90 |

0-1.2 |

8 |

5.0 |

6-8 |

300-600 |

4-4.5 |

160 |

80 |

160 |

80 | |||

|

G40-3 |

24.90 |

0-1.8 |

8 |

4.8 |

6-8 |

300-500 |

5.5-7.5 |

160 |

80 |

160 |

80 | |||

|

G40-4 |

24.90 |

0-2.4 |

8 |

4.5 |

6-8 |

300-500 |

7.5-11 |

180 |

100 |

145 |

65 | |||

|

G50-1 |

49.62 |

0-0.6 |

10 |

10.5 |

8-13 |

300-500 |

4-5.5 |

160 |

80 |

160 |

80 |

2.3.4.5 | ||

|

G50-2 |

49.62 |

0-1.2 |

10 |

10.5 |

8-13 |

300-500 |

7.5-11 |

170 |

100 |

160 |

80 | |||

|

G50-3 |

49.62 |

0-1.8 |

10 |

10.0 |

8-13 |

300-500 |

11-15 |

200 |

125 |

180 |

100 | |||

|

G50-4 |

49.62 |

0-2.4 |

10 |

10.0 |

8-13 |

250-400 |

15-18.5 |

200 |

125 |

180 |

100 | |||

|

G60-1 |

103.91 |

0-0.6 |

11 |

20.0 |

13-20 |

300-450 |

7.5-11 |

170 |

100 |

160 |

80 |

2.3.5. 6.7 | ||

|

G60-2 |

103.91 |

0-1.2 |

11 |

20.0 |

13-20 |

300-450 |

11-15 |

170 |

100 |

160 |

80 | |||

|

G60-3 |

103.91 |

0-1.8 |

11 |

20.0 |

13-20 |

300-400 |

15-18.5 |

200 |

125 |

180 |

100 | |||

|

G60-4 |

103.91 |

0-2.4 |

11 |

19.0 |

13-20 |

300-400 |

18.5-22 |

200 |

125 |

180 |

100 | |||

|

G70-1 |

105.10 |

0-0.6 |

13 |

24.0 |

20-24 |

300-450 |

11-15 |

200 |

125 |

180 |

100 | |||

|

G70-2 |

105.10 |

0-1.2 |

13 |

24.0 |

20-24 |

250-400 |

15-18.5 |

200 |

125 |

180 |

100 | |||

|

G70-A1 |

105.12 |

0-0.6 |

13 |

30.0 |

24-30 |

300-450 |

11-15 |

210 |

125 |

210 |

125 | |||

|

G85-1 |

221.60 |

0-0.6 |

15 |

43.0 |

30-35 |

250-350 |

15-18.5 |

210 |

125 |

210 |

125 | |||

|

G85-2 |

177.60 |

0-1.2 |

15 |

35.0 |

28-53 |

250-350 |

18.5-22 |

210 |

125 |

210 |

125 | |||

|

G85-3 |

201.60 |

0-1.8 |

15 |

40.0 |

30-35 |

250-350 |

30-37 |

280 |

200 |

295 |

200 | |||

|

G85-4 |

198.50 |

0-2.4 |

15 |

39.0 |

25-32 |

200-300 |

37-45 |

280 |

200 |

295 |

200 |

2.3.5. 6.7.8 | ||

|

G105-1 |

400.43 |

0-0.6 |

18 |

74.0 |

35-50 |

250-350 |

22-30 |

280 |

200 |

295 |

200 | |||

|

G105-2 |

400.43 |

0-1.2 |

18 |

74.0 |

35-50 |

250-350 |

37-45 |

280 |

200 |

295 |

200 |

2.3.5. 7.8.9 | ||

|

G110-1 |

532.40 |

0-0.6 |

24 |

105.0 |

50-80 |

200-300 |

22-30 |

280 |

200 |

295 |

200 | |||

|

G110-2 |

532.40 |

0-1.2 |

24 |

105.0 |

50-80 |

200-300 |

30-37 |

280 |

200 |

295 |

200 | |||

|

G110-3 |

532.40 |

0-1.8 |

24 |

100.0 |

50-80 |

200-300 |

37-45 |

280 |

200 |

295 |

200 | |||

|

G110-4 |

530.40 |

0-2.4 |

24 |

98.0 |

45-76 |

180-280 |

45-75 |

280 |

200 |

295 |

200 | |||

|

G120-1 |

764.64 |

0-0.6 |

30 |

146.0 |

80-110 |

200-300 |

30-37 |

280 |

200 |

295 |

200 | |||

|

G120-2 |

764.64 |

0-1.2 |

30 |

146.0 |

80-110 |

200-300 |

37-45 |

280 |

200 |

295 |

200 | |||

|

G135-1 |

835.58 |

0-0.6 |

35 |

160.0 |

110-130 |

150-280 |

37-45 |

280 |

200 |

295 |

200 | |||

|

G135-2 |

835.58 |

0-1.2 |

35 |

160.0 |

110-130 |

150-280 |

55-75 |

280 |

200 |

295 |

200 | |||

二、根據泵輸送介質的理化性能選擇泵的材料組合

|

天然橡膠 NR |

丁晴橡(xiàng)膠 NBR |

食品(pǐn)橡(xiàng)膠 FOOD-ORTENTED RUBBER |

乙丙橡膠 EPDM |

氟橡膠(jiāo) FPM |

|

水(含汙水) Water (includng waste water) |

◎ |

◎ |

● |

◎ |

● |

|

動、植物油 Animal oil and vegetable oil |

× |

◎ |

● |

× |

◎ |

|

礦物油(yóu) Mineral oil |

× |

● |

● |

× |

◎ |

|

氨水 Ammonia water |

× |

● |

● |

× |

× |

|

脂(zhī)肪族濃劑 Fatty solvernts |

× |

× |

× |

× |

● |

|

芳香族濃劑(jì) Aromatic solvents |

× |

× |

× |

× |

● |

|

濃堿 Thick alkaline |

● |

● |

● |

● |

● |

|

濃硝酸 thick nitric acid |

× |

× |

× |

× |

▲ |

|

冰醋酸 glacial acetic acid |

× |

● |

● |

× |

● |

|

稀硫酸 thin sulfuric acid |

× |

× |

× |

● |

● |

|

濃硫酸 thick sulfuric acid |

× |

× |

× |

▲ |

● |

|

稀鹽酸 thin hydrochioric acid |

● |

● |

● |

● |

● |

|

濃鹽酸 thick hydrochioric acid |

× |

× |

× |

● |

● |

|

熱水 Hot water |

× |

▲ |

▲ |

● |

× |

|

汽油(yóu) Gasoline |

× |

● |

● |

× |

● |

|

煤油 Kerosene |

× |

● |

● |

× |

◎ |

|

柴油 Diesel oil |

× |

● |

● |

× |

● |

|

氯化烴 Chiorated hydrocarbon |

× |

× |

× |

× |

▲ |

|

含酮類物料 Ketone containing materials |

× |

× |

× |

× |

▲ |

|

含醇類物料(liào) Alcohol containing materials |

● |

● |

● |

● |

● |

|

含脂類物料 Fat containing materials |

× |

× |

× |

● |

× |

|

含醚類物料 Easter containing materials |

× |

× |

× |

● |

× |

|

泥漿 Slurry |

● |

● |

▲ |

● |

▲ |

|

耐高溫度 Max.temperrature resistance |

70℃ |

90℃ |

90℃ |

180℃ |

130℃ |

|

耐磨性 Wear resistance |

◎ |

● |

● |

◎ |

◎ |

|

耐(nài)老化 Aging resistance |

● |

● |

● |

◎ |

◎ |

|

耐臭氧 Ozene resistance |

× |

× |

× |

◎ |

◎ |

|

耐輻射 Radiation resistance |

▲ |

▲ |

▲ |

▲ |

× |

|

耐(nài)燃性 Fire reasistance |

× |

● |

● |

◎ |

× |

|

抗蒸汽 Steam resistance |

● |

● |

● |

◎ |

◎ |

注:a、食品橡膠不含對人體有害的(de)添加劑

NOte:a.the food-oriented rubber does not contain assitives detrimental to human health

b、◎優 ●良 ▲一般 ×不行

|

轉子、過流部(bù)件材質(zhì) Aterials for rotor and overcurrent parts |

性能用途 Performance and applications |

|

45 HT200 |

防腐能力差,適用一般介質 With poor corrosion resistance, it is suitable for ordinary media. |

|

1Cr18Ni9Ti ZG1Cr18Ni9Ti |

耐一般腐鍾介質 resist ordinary corrosive media |

|

1Cr8Ni12Mo2Ti ZG1Cr18Ni12M02Ti |

耐酸堿 resist acids and alkaline |

三、如果介質中含有顆粒狀固體或纖維物時,應開始從下表中選擇適(shì)用的小規格的(de)泵。

按輸(shū)送介(jiè)質中含有大固體顆粒直(zhí)徑(jìng)和纖維長度選泵。

泵規格:

A、G型泵(單(dān)位:mm)

A、G type pumps

|

泵規格 Pumps specification |

G15 |

G25 |

G35 |

G40 |

G50 |

G60 |

G70 |

G85 |

G110 |

G120 |

G135 |

|

允許大顆粒直徑 |

3 |

5 |

6 |

8 |

10 |

12 |

13 |

15 |

24 |

30 |

35 |

|

允許大(dà)纖(xiān)維長度 |

40 |

60 |

80 |

100 |

120 |

150 |

160 |

200 |

280 |

300 |

520 |

B、TYG型泵(單位:mm)

B、TYG type pumps

|

泵規格 Pumps Specification |

TYG2 |

TYG3 |

TYG4 |

TYG5 |

TYG6 |

TYG8 |

TYG10 |

TYG12 |

TYG14 |

|

允許大顆粒直徑 |

3 |

4 |

6 |

8 |

10 |

13 |

17 |

20 |

24 |

|

允許大(dà)纖維長度 |

25 |

37 |

50 |

63 |

75 |

100 |

125 |

150 |

175 |

介質中固體的含量(liàng)一般不超過40%,如固體為粉末微粒時含(hán)量高可達60%或(huò)更(gèng)高,如水煤(méi)液等。

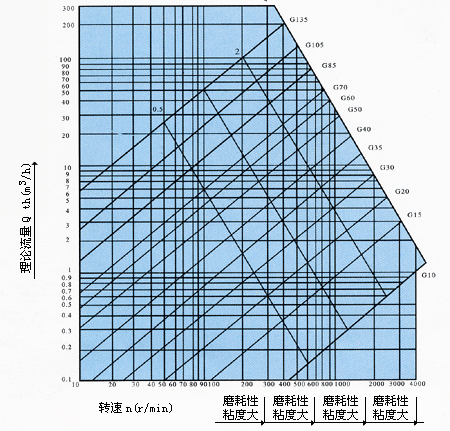

四、按泵輸送不同的介質時的轉速範圍

五、按(àn)介質含有磨(mó)蝕性物料情況,泵所允許的高運行轉速。

A、G型泵

|

泵規格 |

無磨蝕 No wear |

輕磨蝕 Light wea |

中等磨(mó)蝕 Moderrate wear |

嚴(yán)重磨蝕(shí) Serious wear | |

|

G15 |

nmax(r/min) |

2570 |

1290 |

720 |

385 |

|

Qmax(m3/h) |

2.15 |

1.08 |

0.6 |

0.32 | |

|

G25 |

nmax(r/min) |

1575 |

780 |

550 |

275 |

|

Qmax(m3/h) |

5.46 |

2.7 |

1.91 |

0.95 | |

|

G35 |

nmax(r/min) |

1250 |

720 |

520 |

265 |

|

Qmax(m3/h) |

8.77 |

5.05 |

3.65 |

1.86 | |

|

G40 |

nmax(r/min) |

1035 |

685 |

490 |

255 |

|

Qmax(m3/h) |

15.41 |

10.2 |

7.29 |

3.8 | |

|

G50 |

nmax(r/min) |

880 |

610 |

440 |

245 |

|

Qmax(m3/h) |

24.68 |

17.11 |

12.34 |

6.87 | |

|

G60 |

nmax(r/min) |

755 |

555 |

385 |

230 |

|

Qmax(m3/h) |

38.23 |

28.11 |

19.5 |

11.65 | |

|

G70 |

nmax(r/min) |

725 |

550 |

380 |

220 |

|

Qmax(m3/h) |

42.87 |

32.53 |

22.47 |

13.01 | |

|

G85 |

nmax(r/min) |

635 |

530 |

355 |

215 |

|

Qmax(m3/h) |

71.75 |

59.89 |

40.11 |

24.29 | |

|

G110 |

nmax(r/min) |

500 |

460 |

310 |

180 |

|

Qmax(m3/h) |

146.93 |

135.18 |

91.1 |

52.9 | |

|

G120 |

nmax(r/min) |

450 |

395 |

260 |

160 |

|

Qmax(m3/h) |

195.34 |

171.47 |

112.86 |

69.46 | |

|

G135 |

nmax(r/min) |

435 |

380 |

250 |

150 |

|

Qmax(m3/h) |

218.09 |

190.52 |

125.34 |

75.2 |

TYG型轉定子:

B、TYG型泵

|

泵規格 |

無磨蝕 NO wear |

輕磨蝕 Light wear |

中等磨(mó)蝕 Moderate wear |

嚴重磨蝕(shí) Serious wear | |

|

TYG2 |

nmax(r/min) |

3000 |

1600 |

890 |

475 |

|

Qmax(m3/h) |

3.66 |

1.95 |

1.09 |

0.58 | |

|

TYG3 |

nmax(r/min) |

2110 |

1060 |

740 |

370 |

|

Qmax(m3/h) |

8.82 |

4.43 |

3.09 |

1.55 | |

|

TYG4 |

nmax(r/min) |

1580 |

950 |

665 |

355 |

|

Qmax(m3/h) |

15.77 |

9.48 |

6.64 |

3.54 | |

|

TYG5 |

nmax(r/min) |

1270 |

890 |

635 |

350 |

|

Qmax(m3/h) |

24.87 |

17.43 |

12.43 |

6.85 | |

|

TYG6 |

nmax(r/min) |

1190 |

830 |

595 |

330 |

|

Qmax(m3/h) |

40.5 |

28.25 |

20.25 |

11.23 | |

|

TYG8 |

nmax(r/min) |

935 |

695 |

485 |

275 |

|

Qmax(m3/h) |

75.32 |

55.99 |

39.07 |

22.15 | |

|

TYG10 |

nmax(r/min) |

780 |

610 |

415 |

245 |

|

Qmax(m3/h) |

122.62 |

95.89 |

65.24 |

38.51 | |

|

TYG12 |

nmax(r/min) |

680 |

595 |

390 |

240 |

|

Qmax(m3/h) |

185.14 |

162 |

106.18 |

65.34 | |

|

TYG14 |

nmax(r/min) |

600 |

540 |

340 |

215 |

|

Qmax(m3/h) |

259.2 |

233.28 |

146.88 |

92.88 |

2、各類(lèi)含磨蝕(shí)性物料介質舉例:

A、無磨蝕介質:淡水、油、漿汁、甘油、血液、肥皂水等;

B、輕磨蝕(shí)介(jiè)質:軟(ruǎn)質泥(ní)漿(jiāng),含水95%以上(shàng)的汙泥,如活性汙泥水,精糖廢液,農畜屎尿,工(gōng)業廢等;

C、中等磨蝕介質:含有固體物料的泥漿,含水85%以上的泥漿,如塗料(liào),糖蜜,研削液,石膏泥漿等;

D、嚴重(chóng)磨蝕介質:水煤(méi)漿,含有磨蝕性物質的漿液(yè),含水率50%以上的汙泥,如研(yán)磨液,溫泉泥,PVC漿料

,粘土,脫水占結劑等。

D、輸送(sòng)介質的粘度也是選(xuǎn)泵需要的一個因素,泵的運行(háng)轉速隨著介質的粘度而降低,若(ruò)粘度達(dá)到150000

mpa以上時,一般結構的泵無法吸入,則必須增設喂料器等特殊(shū)設計。

六 按泵輸(shū)送(sòng)介質粘度的合適轉速(粘度(dù)單(dān)位:mpa.s)

A、G型

|

泵規格 |

1~1500 |

1500~3000 |

3000~10000 |

10000~25000 |

25000~50000 |

50000~100000 |

100000~150000 |

150000以上 | |

|

G15 |

nmax(r/min) |

1685 |

1265 |

560 |

420 |

280 |

60 |

30 |

|

|

Qmax(m3/h) |

1.41 |

1.06 |

0.47 |

0.35 |

0.23 |

0.05 |

0.025 |

||

|

G25 |

nmax(r/min) |

1110 |

870 |

380 |

280 |

200 |

50 |

25 |

|

|

Qmax(m3/h) |

3.85 |

3.01 |

1.32 |

0.97 |

0.69 |

0.17 |

0.087 |

||

|

G35 |

nmax(r/min) |

1030 |

845 |

350 |

260 |

185 |

50 |

25 |

|

|

Qmax(m3/h) |

7.23 |

5.93 |

2.46 |

1.82 |

1.3 |

0.35 |

0.175 |

||

|

G40 |

nmax(r/min) |

900 |

700 |

325 |

250 |

175 |

50 |

25 |

|

|

Qmax(m3/h) |

12.56 |

9.77 |

4.54 |

3.49 |

2.44 |

0.698 |

0.349 |

||

|

G50 |

nmax(r/min) |

745 |

620 |

300 |

225 |

150 |

50 |

25 |

|

|

Qmax(m3/h) |

20.89 |

17.39 |

8.41 |

6.31 |

4.21 |

1.4 |

0.7 |

||

|

G60 |

nmax(r/min) |

660 |

565 |

300 |

225 |

150 |

50 |

25 |

|

|

Qmax(m3/h) |

33.42 |

28.61 |

15.19 |

11.39 |

7.6 |

2.53 |

1.266 |

||

|

G70 |

nmax(r/min) |

635 |

540 |

300 |

225 |

150 |

50 |

25 |

|

|

Qmax(m3/h) |

37.55 |

29.57 |

17.74 |

13.31 |

8.87 |

2.96 |

1.48 |

||

|

G85 |

nmax(r/min) |

575 |

500 |

300 |

225 |

150 |

50 |

25 |

|

|

Qmax(m3/h) |

64.97 |

56.5 |

33.9 |

25.42 |

16.95 |

5.65 |

2.82 |

||

|

G110 |

nmax(r/min) |

520 |

450 |

300 |

225 |

150 |

50 |

25 |

|

|

Qmax(m3/h) |

152.81 |

132.24 |

88.16 |

66.12 |

44.08 |

14.69 |

7.35 |

||

|

G120 |

nmax(r/min) |

450 |

400 |

300 |

225 |

150 |

50 |

25 |

|

|

Qmax(m3/h) |

195.34 |

173.64 |

130.23 |

97.67 |

65.11 |

21.7 |

10.85 |

||

|

G135 |

nmax(r/min) |

410 |

365 |

300 |

225 |

150 |

50 |

25 |

|

|

Qmax(m3/h) |

203.53 |

181.19 |

148.93 |

111.69 |

74.46 |

24.82 |

12.41 |

B、TYG型(xíng)泵

|

泵規格(gé) |

1~1500 |

1500~3000 |

3000~10000 |

10000~25000 |

25000~50000 |

50000~100000 |

100000~150000 |

150000以上 | |

|

TYG2 |

nmax(r/min) |

1800 |

1350 |

600 |

450 |

300 |

60 |

30 |

|

|

Qmax(m3/h) |

2.2 |

1.65 |

0.73 |

0.55 |

0.366 |

0.073 |

0.037 |

||

|

TYG3 |

nmax(r/min) |

1250 |

980 |

420 |

310 |

220 |

50 |

25 |

|

|

Qmax(m3/h) |

5.23 |

4.1 |

1.76 |

1.3 |

0.92 |

0.21 |

0.1 |

||

|

TYG4 |

nmax(r/min) |

1100 |

900 |

375 |

275 |

200 |

50 |

25 |

|

|

Qmax(m3/h) |

10.98 |

8.89 |

3.74 |

2.75 |

2 |

0.5 |

0.25 |

||

|

TYG5 |

nmax(r/min) |

960 |

745 |

345 |

265 |

185 |

50 |

25 |

|

|

Qmax(m3/h) |

18.8 |

14.59 |

6.76 |

5.19 |

3.62 |

0.98 |

0.49 |

||

|

TYG6 |

nmax(r/min) |

830 |

690 |

330 |

250 |

165 |

50 |

25 |

|

|

Qmax(m3/h) |

28.28 |

23.48 |

11.23 |

8.51 |

5.62 |

1.7 |

0.85 |

||

|

TYG8 |

nmax(r/min) |

675 |

575 |

310 |

240 |

160 |

50 |

25 |

|

|

Qmax(m3/h) |

54.37 |

46.32 |

24.97 |

19.33 |

12.89 |

4.03 |

2.01 |

||

|

TYG10 |

nmax(r/min) |

610 |

530 |

300 |

225 |

150 |

50 |

25 |

|

|

Qmax(m3/h) |

95.89 |

83.32 |

47.16 |

35.37 |

23.58 |

7.86 |

3.93 |

||

|

TYG12 |

nmax(r/min) |

525 |

450 |

300 |

225 |

150 |

50 |

25 |

|

|

Qmax(m3/h) |

142.94 |

122.52 |

81.68 |

61.26 |

40.84 |

13.61 |

6.81 |

||

|

TYG14 |

nmax(r/min) |

495 |

430 |

300 |

225 |

150 |

50 |

25 |

|

|

Qmax(m3/h) |

213.84 |

185.76 |

129.6 |

97.2 |

64.8 |

21.6 |

10.8 |

2、表列流量Qmax係泵壓p=0時,相應轉nmax的理論值。

3、粘度超過150000mpa.s的介質,泵需要特殊設計。

根據以上表格、選定適合的(de)泵,擇(zé)其大規格者,再按(àn)輸送壓力要求確(què)定泵的級數請(qǐng)參(cān)看下表。

七、泵輸送不同介質時每(měi)級允許的增壓

|

泵規格 pump sepcification |

介質含磨蝕物情況 Media with abrasives | |||

|

無磨蝕 NO wear |

輕磨蝕 Low wear |

中等磨蝕 Moderate wear |

嚴重磨蝕 serious wear | |

|

G15 |

0.45 |

0.4 |

0.3 |

0.2 |

|

G25~135 |

0.6 |

0.5 |

0.35 |

0.2 |

|

TYG2 |

0.55 |

0.5 |

0.35 |

0.25 |

|

TYG3~14 |

0.75 |

0.6 |

0.4 |

0.25 |

八、泵輸送粘滯性介質所需功率倍數

|

粘度(dù)(mpa) Viscosity(mpa) |

0~10000 |

10000~25000 |

25000~50000 |

50000~100000 |

100000~150000 |

150000以(yǐ)上 |

|

功率倍數 Multitude of power |

1.0 |

1.05 |

1.1 |

1.2 |

1.25 |

特殊設計 Special design |

九(jiǔ)、軸封和泵(bèng)部材料組合

|

軸 封 shaft seal |

| ||||

|

材

料 組 合 Material composition |

代(dài)號 codes |

轉子 Rotors |

定子內襯 Liner for stators |

過流部件 Overcurrent parts | |

|

M101 |

45 |

天然橡膠 Natual rubber |

45、HT200 | ||

|

M102 |

1Gr18Ni9Ti |

天然橡膠(jiāo) Natual rubber |

1Cr18Ni9Ti、ZG1CR18Ni9Ti | ||

|

M103 |

45 |

丁(dīng)腈橡膠 Paracril |

45、HT200 | ||

|

M104 |

1Gr18Ni9Ti |

丁腈橡膠 Paracril |

1Cr18Ni9Ti、ZG1CR18Ni9Ti | ||

|

M105 |

1Gr18Ni9Ti |

食品橡膠 Food-oriented rubber |

1Cr18Ni9Ti、ZG1CR18Ni9Ti | ||

|

M106 |

1Gr18Ni9Ti |

氯磺化聚乙烯膠 sulfochlorinated polyethyene rubber |

1Cr18Ni9Ti、ZG1CR18Ni9Ti | ||

|

M107 |

1Gr18Ni12Mo2Ti |

氯磺化聚乙烯膠 sulfochlorinated polyethyiene rubber |

1Cr18Ni12Mo2Ti、ZG1CR18Ni12Mo2Ti | ||

|

M108 |

45 |

乙丙橡(xiàng)膠 EPDM |

45、HT200 | ||

|

M109 |

1Gr18Ni9Ti |

乙丙橡膠 EPDM |

1Cr18Ni9Ti、ZG1CR18Ni9Ti | ||

|

M110 |

1Gr18Ni9Ti |

氟橡膠 fLUORUBBER |

1Cr18Ni9Ti、ZG1CR18Ni9Ti | ||

|

M111 |

1Gr18Ni12Mo2Ti |

氟橡膠 Fluorubber |

1Cr18Ni12Mo2Ti、ZG1CR18Ni12Mo2Ti | ||

| 注:食品橡膠不含對人體有害的添加劑 Note;The food-oriented rubber does not contain assitives detrimental to human health | |||||

感謝您訪問我們揚(yáng)子江泵業的網站www.a-vested-interest.com,如有任何水(shuǐ)泵疑問我們一定會盡心(xīn)盡力為您提供優質(zhì)的服(fú)務。